As a leading fitness equipment manufacturer in the industry, Baopeng has a stable supply capacity and quality management system. From raw materials, production to delivery, the whole process quality control ensures that the products meet the highest standards in the industry. This is an important foundation for customer trust and the core strength of Baopeng’s deep market penetration. At the same time, Baopeng’s CPU/TPU products can pass multiple international certifications such as REACH and ROHS to meet the diverse needs of customers.

As people are concerned about some unfriendly materials such as PVC and rubber, we use more environmentally friendly and durable PU materials to replace them. Through the structure and section description, you will see that every detail shows our persistent pursuit of quality. Baopeng dumbbells make training safer, more comfortable and more efficient!

*1. Dumbbell structure and cross-section description

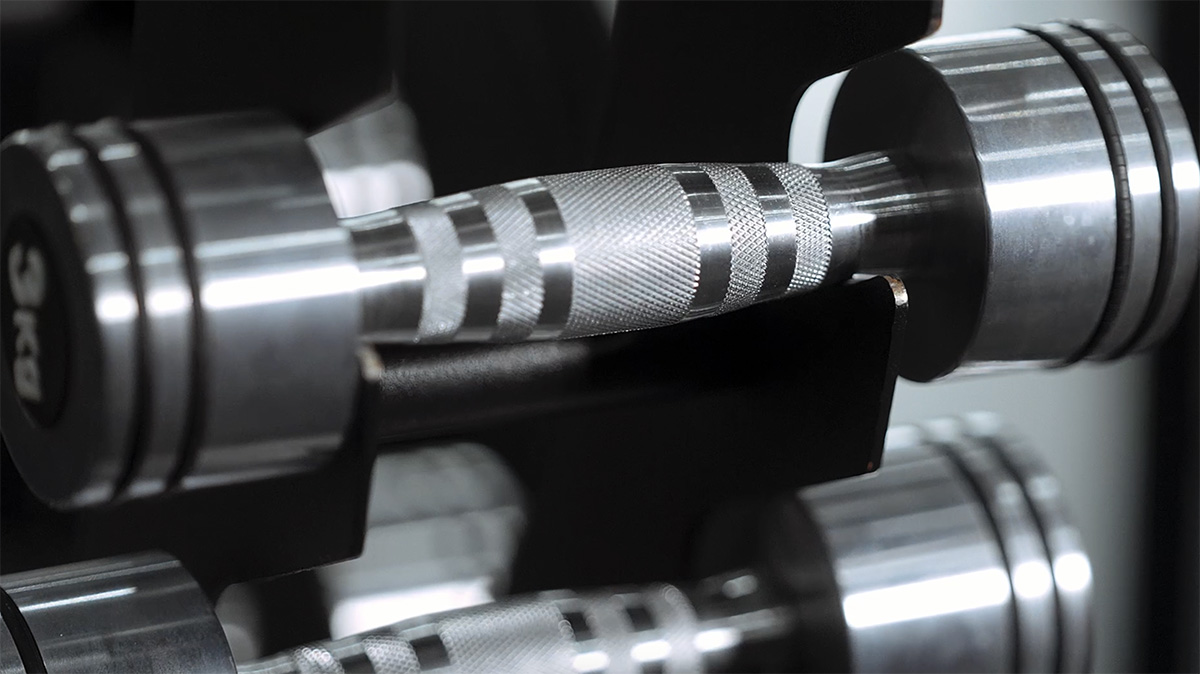

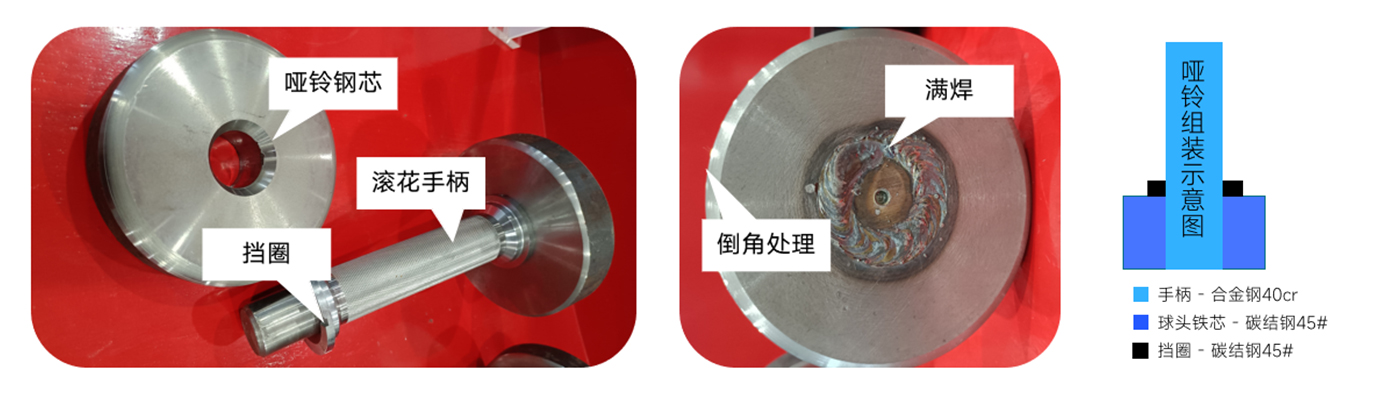

The ball head iron core of the dumbbell is made of carbon steel 45#, and the handle is made of A3 steel and alloy steel 40cr according to weight. To ensure the high density, high strength and high durability of the dumbbell, each batch of round steel undergoes strict chemical composition analysis and physical performance tests to ensure that it meets international quality standards.

Full welding is based on the tight fit between the steel core and the handle. The two same materials are welded at the top of the bevel to ensure double tightness.

* Generally, specifications above 10kg use punching welding technology

It is strongly recommended that brand customers pay attention to the “chamfering treatment” of the steel core

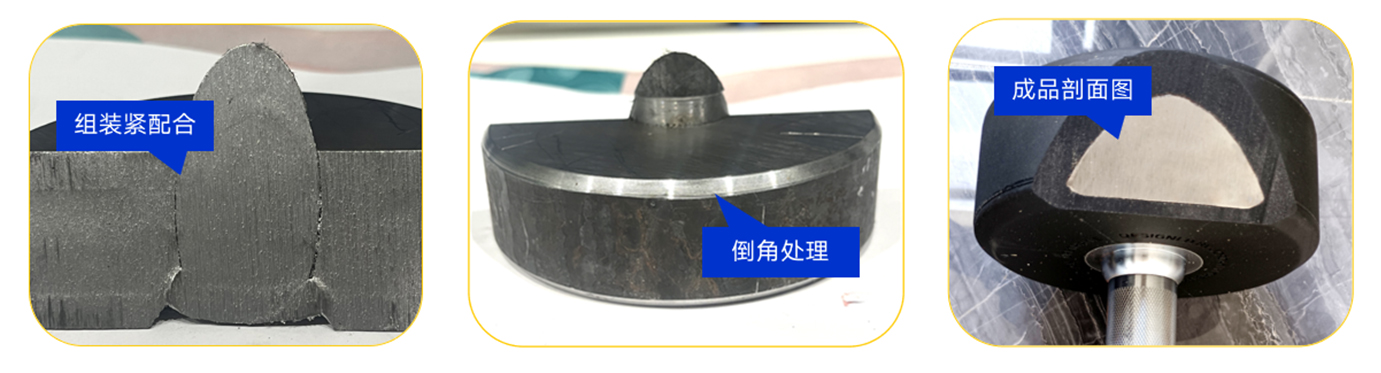

[Chamfering] To prevent the surface rubber layer from cracking prematurely during the use of dumbbells, Baopeng will perform “chamfering” after the steel is sawed when producing dumbbells to improve product quality and reduce after-sales service.

[Assembly tight fit] The data of the center hole of the steel core and the size of the two ends of the handle are precisely calculated to achieve a 0-to-0 tight fit, preventing the dumbbells from falling multiple times during use and becoming loose.

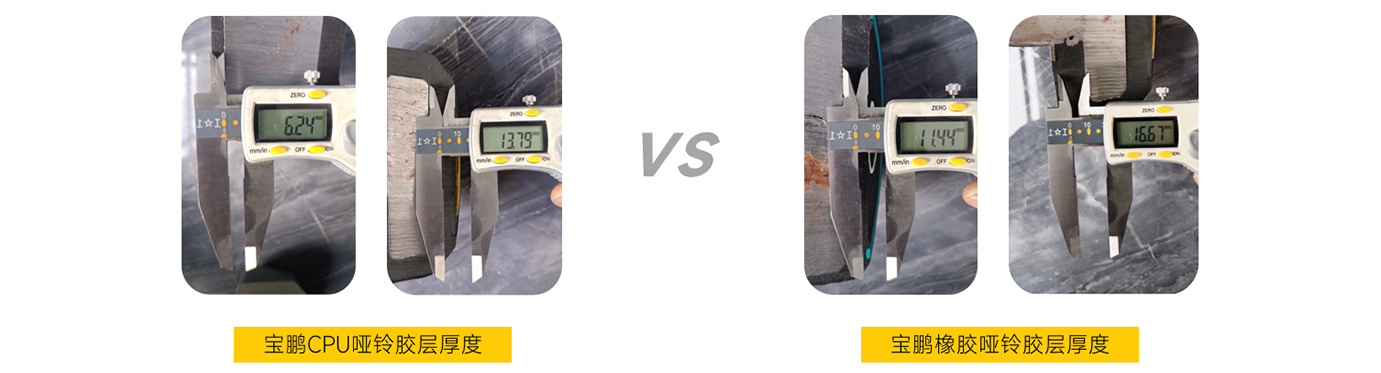

*2. Rubber layer thickness description – CPU dumbbells VS rubber dumbbells

As a professional manufacturer of commercial dumbbells, Baopeng has years of experience in production, data optimization and testing. We have found that if the glue layer on one side of the CPU dumbbell is controlled within the range of 6-18mm and the glue layer on one side of the rubber dumbbell is controlled within the range of 10-20mm, the probability of passing the violent drop test from a height of 2 meters is 99.8%. The thickness of the rubber layer directly affects the transaction rate and quality of the product. We strictly control the thickness of the rubber layer to ensure that the product meets our drop test standards.

Why Choose Baopeng?

At Nantong Baopeng Fitness Equipment Technology Co., Ltd., we combine over 30 years of experience with cutting-edge manufacturing techniques to produce top-tier fitness equipment. Whether you need CPU or TPU dumbbells, weight plates, or other products, our materials meet global safety and environmental standards.

Want to learn more? Contact us now!

Reach out to our friendly sales team at zhoululu@bpfitness.cn today.

Let’s discuss how we can create high-quality, eco-friendly fitness solutions for you.

Don’t wait—your perfect fitness equipment is just an email away!

Post time: Apr-23-2025