Amid the deep integration of China’s "dual-carbon" strategy and the high-quality development of the sports industry, Nantong Baopeng Fitness Equipment Technology Co., Ltd. has actively responded to national policies, embedding green principles across its entire production chain. Through systematic initiatives such as raw material innovation, process upgrades, and energy transformation, the company is pioneering a sustainable development path for the sports manufacturing sector. Recently, reporters visited the factory to decode the "green secrets" behind its eco-friendly practices.

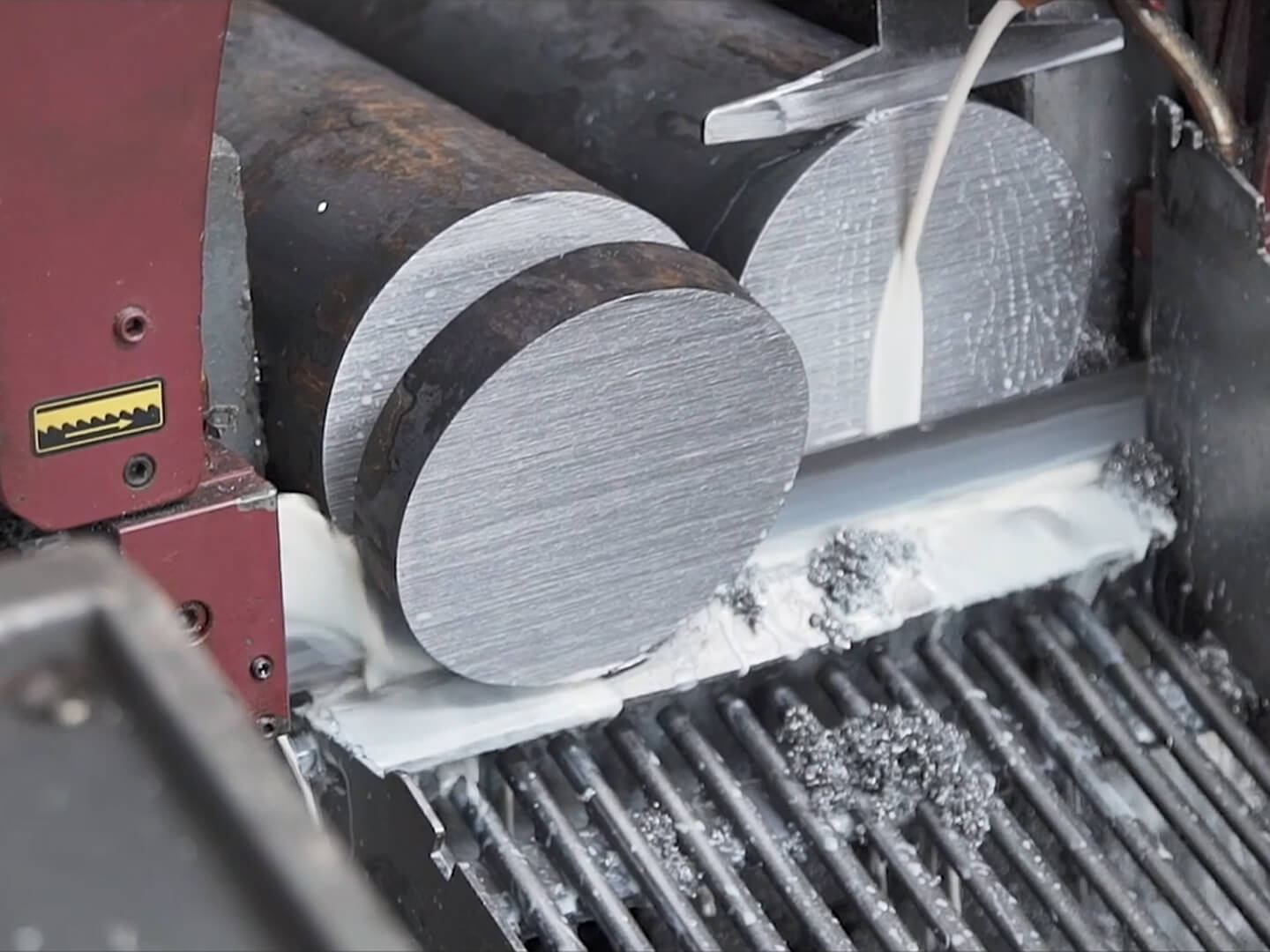

Source Control: Building a Green Supply Chain System

Baopeng Fitness sets strict standards from the raw material procurement stage. All of our raw materials comply with the EU REACH standard and eliminate harmful substances such as heavy metals and volatile organic compounds. Beyond requiring suppliers to provide full-component test reports, Baopeng evaluates partners based on their "green factory" qualifications and adoption of clean production processes. Currently, 85% of its suppliers have completed eco-friendly upgrades. For instance, the TPU shell of its star product, the Rainbow Dumbbell, uses eco-friendly polymers, while its iron core is made of low-carbon steel, reducing the carbon footprint per unit by 15% compared to traditional methods.

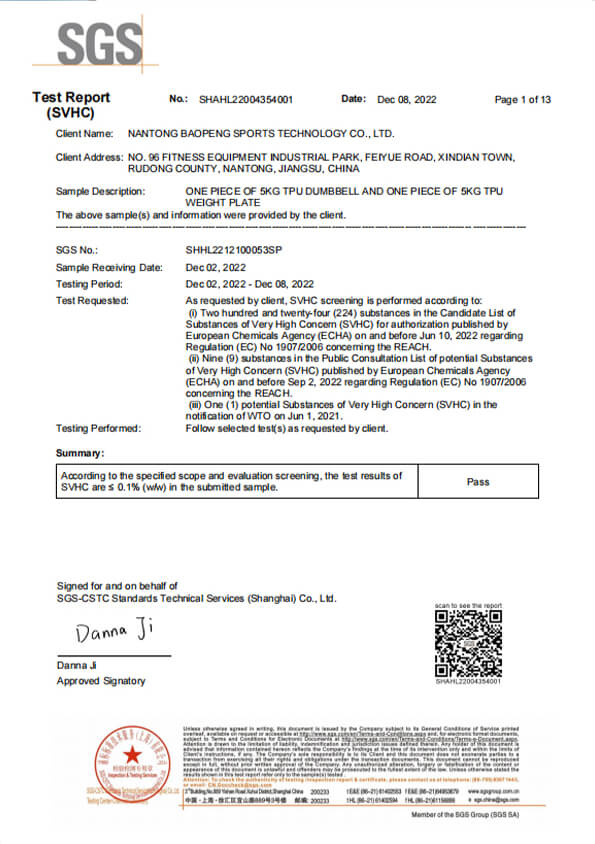

Process Innovation: Low-Carbon Smart Manufacturing Drives Emission Reduction

Inside Baopeng’s intelligent production workshop, fully automated cutting machines and press machines operate efficiently with low energy consumption. The company’s technical lead revealed that the production line’s overall energy consumption in 2024 decreased by 41% compared to 2019, cutting annual carbon emissions by approximately 380 tons. In the coating process, the factory has replaced traditional oil-based paints with water-based eco-friendly alternatives, reducing volatile organic compounds (VOCs) emissions by over 90%. Advanced filtration systems ensure that discharge metrics exceed national standards.

Equally noteworthy is Baopeng’s scientific waste management system. Metal scraps are sorted and remelted, while hazardous waste is professionally handled by certified companies like Lvneng Environmental Protection, achieving 100% compliant disposal.

Solar Empowerment: Clean Energy Illuminates the Green Factory

The factory roof boasts a sprawling 12,000-square-meter photovoltaic panel array. This solar system generates over 2.6 million kWh annually, meeting more than 50% of the plant’s electricity needs and reducing standard coal consumption by roughly 800 tons per year. Over five years, the project is projected to cut carbon emissions by 13,000 tons—equivalent to the ecological benefits of planting 71,000 trees.

Government-Enterprise Collaboration: Building a Sports Industry Ecosystem

The Nantong Sports Bureau highlighted Baopeng’s role as an industry benchmark: "Since 2023, Nantong has implemented the *Three-Year Action Plan for Synergizing Pollution Reduction and Carbon Mitigation (2023–2025)*, which emphasizes ‘green and low-carbon development actions.’ This initiative optimizes industrial structures, supports enterprises in adopting clean energy and eco-friendly processes, and provides policy incentives for qualified projects. We encourage more companies to integrate ESG (environmental, social, governance) principles into their strategies."

Looking ahead, Baopeng’s General Manager Li Haiyan expressed confidence: "Environmental protection is not a cost but a competitive edge. We are collaborating with environmental experts to develop more biodegradable materials and aim to establish a ‘low-carbon circular factory.’ Our goal is to offer a replicable ‘Nantong model’ for the green transformation of sports manufacturing." Driven by both policy guidance and corporate innovation, this path balancing ecological and economic benefits is injecting green momentum into China’s vision of becoming a sports powerhouse.

Post time: Apr-24-2025